Mazak Go Green Strategy

Mazak’s business philosophy factors sustainability into all its operations. From machine tool, design, development, manufacture, usage and eventual renewal. A continuous improvement strategy focuses on improving the sustainability of Mazak machine tools four times by 2030 compared to 2010.

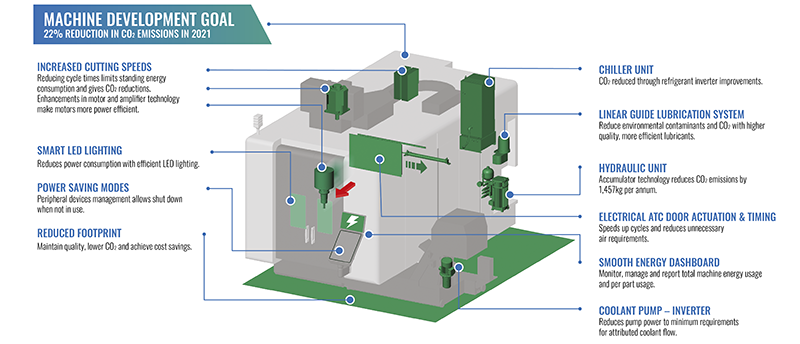

As a clear example, the next-generation of 5-axis simultaneous Vertical Machining Centre VARIAXIS i-800 NEO delivers machining capability in a faster, more compact machine. In addition, enhanced technologies are incorporated into the design that reduces running CO2 emissions by 22.7% compared to the previous model.

Also, the new QTE compact turning centres incorporate technologies that help reduce energy consumption, save costs and benefit the environment. Using standards set out by the Green House Gas Protocol, Mazak Smooth Technology offers functions to support customers’ requirements in measuring, analysing and improving the energy and subsequent CO2 footprint of the parts they produce.

[Click on the photo to enlarge]

Green Factories

Mazak’s manufacturing premises in Japan and the UK operate to comprehensive energy and sustainability policies. They maintain the registration of ISO 14001:2015 Environmental Management and ISO 50001 Energy Management. While Japan and Singapore utilise roof space for over 3.5 MW of solar energy production. Local initiatives are supported across Europe with clear objectives to promote sustainability and environmental awareness right through to our customers.

World Research and Development Center

This facility has a "living green roof" on which moss is growing to reduce the heat-island phenomenon contributing to global warming. It is one of the largest green roofs in Asia