Hybrid Multi-Tasking

|

Additive Manufacturing |

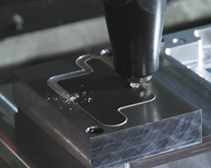

Friction Stir Welding |

Auto Gear |

| Laser Metal Deposition Wire Arc AM |

Friction Stir Welding |

The integration of INTEGREX multi-tasking with gear cutting and measurement |