HCR-5000

High precision machining of components Simultaneous 5-axis horizontal machining center

- Faster simultaneous 5-axis machining cycle times by high speed acceleration and Jerk

- Large capacity coolant system and machine construction ensures smooth chip disposal

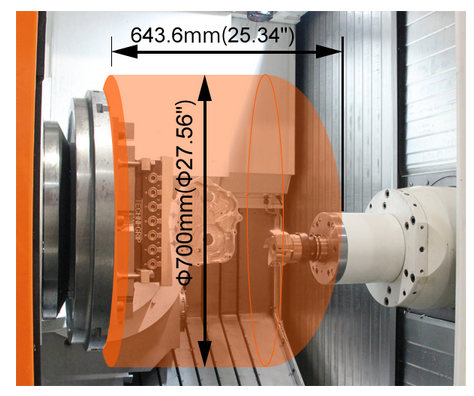

- Max. workpiece dimensions

The maximun workpiece size is the same for both the single table and 2-pallet changer specifications

- 4 types of spindle specifications are available to meet your production requirements - from the standard to the optional high speed, high output specification

- Design focus on ergonomics provides unsurpassed ease of operation

- Excellent accessibility to the table for loading and unloading

- Large window

- Maintenance unit in one central location

- Horizontal machining centers, 5-axis machining centers and multi-tasking machines can be integrated with the HCR-5000 in a PALLETECH system

Machine Specifications

| Standard Machine | Values | |

|---|---|---|

| TRAVEL | X-axis travel (Spindle head cross-wise) | 730 mm |

| Y-axis travel (Spindle head up/down) | 730 mm | |

| Z-axis travel (Table back/forth) | 730 mm | |

| A-axis travel (table tiliting) | 225° (-90° ~ +135°) | |

| C-axis travel (table rotating) | 360° | |

| CAPACITY | Maximum workpiece diameter | 700 mm |

| Maximum workpiece height | 643.6 mm | |

| Maximum workpiece weight (uniformly distributed) | 500 kg | |

| TABLE | Pallet width | 500 mm |

| Pallet length | 500 mm | |

| SPINDLE (STANDARD) | Spindle taper hole | 7/24 taper No. 40 (1/10 taper HSK-A63) |

| Rotational speed (maximum) | 12,000 min-¹ | |

| FEEDRATE | Rapid traverse rate (X-, Y-, Z-) | 60 m/min |

| Rapid traverse rate A-axis | 30 min-¹ | |

| Rapid traverse rate C-axis | 50 min-¹ | |

| ATC & TOOL MAGAZINE | Tool storage capacity (standard) | 40 |

| Max tool diameter (adjacent pockets occupied) | 95 mm | |

| Max tool diameter (adjacent pockets empty) | 170 mm | |

| Max tool length (from gauge line) | 400 mm | |