Yamazaki Mazak is bringing a flavour of Italy back to the UK with its traditional EMO Encore Open House.

Scheduled from the 8-11th December 2015, at Mazak’s European Technology Centre in Worcester, EMO Encore is billed as the ideal opportunity for machine users, who were unable to travel to Milan, to experience the highlights of the show without leaving the UK.

EMO Encore, which will be themed “It’s all about you” in recognition of Mazak’s philosophy of placing its customers first, will feature 22 machines, capable of delivering a machining solution for each individual customer application.

The stars of EMO Encore are likely to be two members of Mazak’s new SMOOTH Technology ‘family’, SmoothX, for 5-axis simultaneous machining, and SmoothG, which has been developed to handle machines with up to 16 axes, with 4-axis in simultaneous motion.

EMO Encore will mark the UK debut for SmoothG, developed for vertical and horizontal machining centres and high performance turning centres. Like SmoothX, it comes equipped with a 19 inch touchscreen, which can be rotated to suit the posture of the operator, and five process home screens that present all critical data in a single page view.

In operation, the touchscreen technology reduces the number of keystrokes required to enter a program by 38% compared to its predecessor. Cycle times are also dramatically reduced through a combination of the latest generation high speed servo drive and motors package, and new high speed processing capability of the CNC capable of achieving speeds of up to 540m/min for 1mm segments– four times faster than its predecessor control. – enabling it to easily respond to the most demanding high speed machining applications.

In operation, the touchscreen technology reduces the number of keystrokes required to enter a program by 38% compared to its predecessor. Cycle times are also dramatically reduced through a combination of the latest generation high speed servo drive and motors package, and new high speed processing capability of the CNC capable of achieving speeds of up to 540m/min for 1mm segments– four times faster than its predecessor control. – enabling it to easily respond to the most demanding high speed machining applications.

Making its UK debut at EMO Encore will be the VARIAXIS i-1050T, the latest and largest addition to Mazak’s highly successful VARIAXIS range of 5-axis machining centres. The machine features a gantry box design with a fully cast structure to ensure maximum stability and accuracy, ideal for machining large workpieces up to dia. 1,250mm x 900mm, with a maximum weight of 2,000Kg. Performance is delivered with a powerful 10,000rpm and 37kW 50 taper spindle, capable of machining a wide range of applications.

This combination of spindle power and rigidity makes the VARIAXIS ideal for complete DONE-IN-ONE processing of complex, large and heavy duty workpieces that also require turning, such as those commonly used in the aerospace sector.

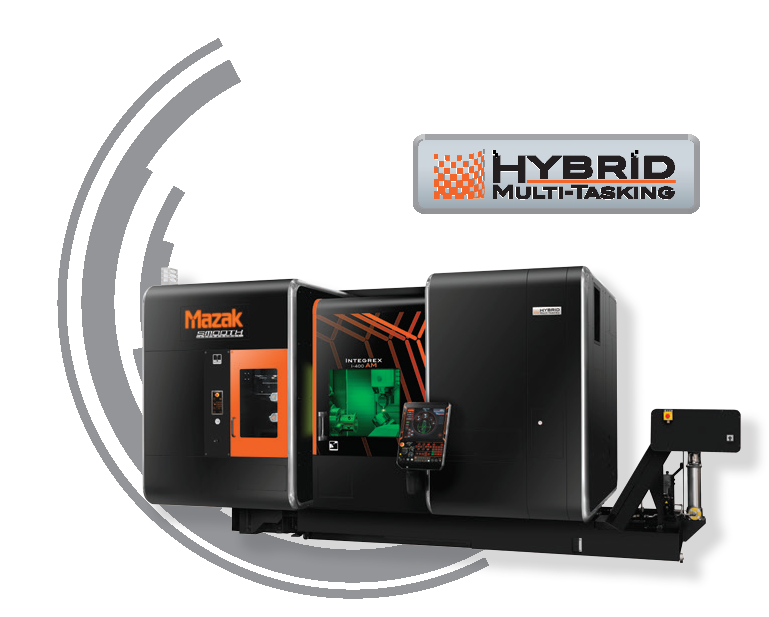

Also on show at EMO Encore will be the new INTEGREX i-400 AM which integrates Direct Energy Deposition additive manufacturing technology into a state-of-the-art 5-axis multi-tasking machine. The i-400 AM makes use of a built-in 1kW fibre laser to melt metallic powder, which is then applied layer by layer via interchangeable cladding heads that are stored in the machine’s standard 36-tool magazine. Once the additive manufacturing process is complete, the machine’s full 5-axis machining capability finishes the component.

Also on show at EMO Encore will be the new INTEGREX i-400 AM which integrates Direct Energy Deposition additive manufacturing technology into a state-of-the-art 5-axis multi-tasking machine. The i-400 AM makes use of a built-in 1kW fibre laser to melt metallic powder, which is then applied layer by layer via interchangeable cladding heads that are stored in the machine’s standard 36-tool magazine. Once the additive manufacturing process is complete, the machine’s full 5-axis machining capability finishes the component.

Specifically, the INTEGREX i-400 AM retains the outstanding performance of the class-leading INTEGREX i-series family, including 50m/min rapid traverse rates, a main spindle capable of delivering 3,300rpm / 30kW and a 12,000rpm / 22kW milling spindle, the perfect combination for a range of challenging applications.

EMO Encore will also feature state-of-the-art laser cutting technology in the form of the OPTIPLEX 3015 Fiber 4kW machine, which is capable of ultra-high speed cutting of medium thickness material and has the ability to cut the finest widths and most difficult reflective materials. Fibre lasers offer lower running costs, due to a circa 80 per cent reduction in oscillator electrical power consumption and a 100 per cent reduction in laser gas consumption, compared to CO2 lasers.

The OPTIPLEX 3015 Fiber has a large side access door and flexible design, and is available in a single pallet or in an optional automated two-pallet version. Critically, the machine has a minimal floor space requirement, which makes it ideal for subcontractors and laser-users requiring a small footprint machine. The OPTIPLEX Nexus 3015 Fiber 3kW is equipped with a Mazak Multi-control torch with unique ZETA-9 technology, which delivers nine separate functions, six set-up and three monitoring, which reduce operator dependency and improves throughput and part quality.

The OPTIPLEX 3015 Fiber has a large side access door and flexible design, and is available in a single pallet or in an optional automated two-pallet version. Critically, the machine has a minimal floor space requirement, which makes it ideal for subcontractors and laser-users requiring a small footprint machine. The OPTIPLEX Nexus 3015 Fiber 3kW is equipped with a Mazak Multi-control torch with unique ZETA-9 technology, which delivers nine separate functions, six set-up and three monitoring, which reduce operator dependency and improves throughput and part quality.

Richard Smith, Managing Director UK and Ireland Sales Division at Yamazaki Mazak, commented: “If you missed EMO Milan then I would advise you not to miss out on EMO Encore, which is bringing the best of Europe’s premier machine tool exhibition back to the UK.

“Our guests will be able to get hands-on with the world’s fastest CNC and our range of state-of-the-art machine tools, many of them making their UK debut, which can transform manufacturing operations by offering unprecedented improvements in productivity and accuracy.”

Find out more and Register