PALLETECH SYSTEM

Manufacturing innovation to meet your requirements today as well as tomorrow

The PALLETECH SYSTEM is designed with the flexibility required for shorter product life cycles, reduced in-process inventory, just-in-time production, and other demands of today's manufacturing environment. Automate your pallet loading, stocking, and changing across horizontal, vertical, 5-axis machining centers, and more.

The PALLETECH SYSTEM is designed with the flexibility required for shorter product life cycles, reduced in-process inventory, just-in-time production, and other demands of today's manufacturing environment. Automate your pallet loading, stocking, and changing across horizontal, vertical, 5-axis machining centers, and more.

We offer the PALLETECH MANUFACTURING CELL (single level) and PALLETECH HIGH RISE SYSTEM (2 or 3 levels) according to your production needs.

Furthermore, the PALLETECH SYSTEM is designed to allow for convenient system expansion after the initial installation to easily respond to increased production requirements in the future.

The PALLETECH SYSTEM reduces costs in three areas:

1. Lower Investment

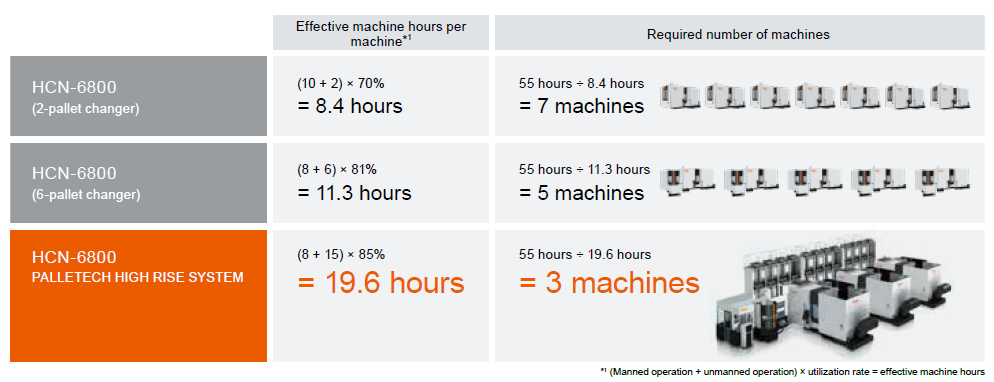

System comparison between HCN-6800 with 2-pallet changer, 6-pallet changer and PALLETECH HIGH RISE SYSTEM.

Daily required machine hours : 55 (55 workpieces with 1 hour cycle time)

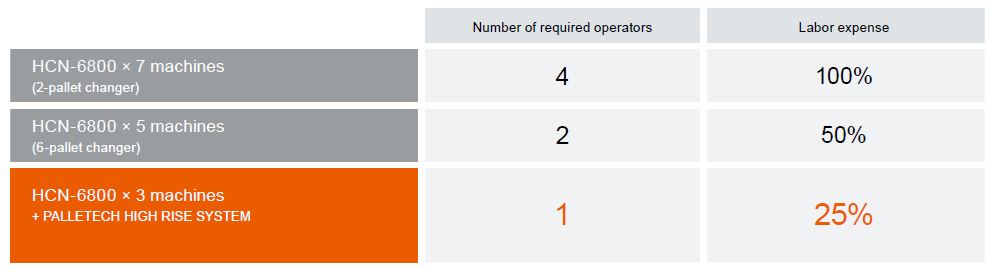

2. Considerable reduction in the number of operators required

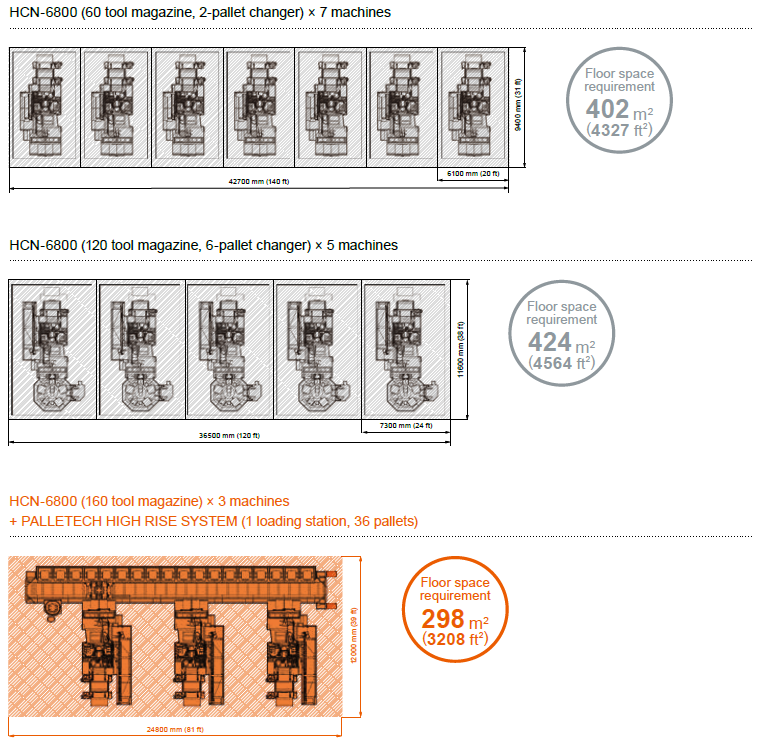

3. Reduction of floor space requirements

To efficiently use limited factory floor space, the PALLETECH SYSTEM provides the best solution.

A PALLETECH HIGH RISE SYSTEM when compared with the 2-pallet changer and 6-pallet changer HCN-6800 is shown below.

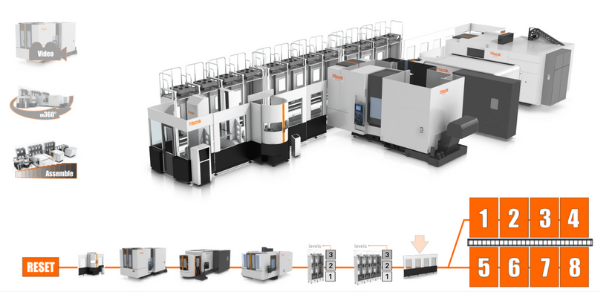

Design your own PALLETECH configuration using our builder

Explore Our PALLETECH builder tool

How does PALLETECH expand to your needs?

Flexible extensibility

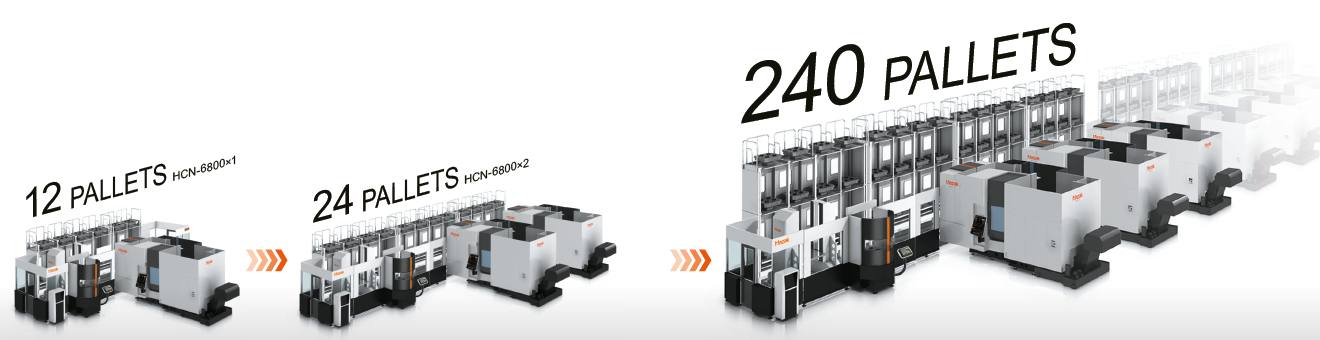

A single machine system can be expanded - pallet stocker(s), loading station(s) and machines can be added in response to increased production requirements after the initial system installation.

Pallet stocker

The rail for the loader and the chip pan are integrated with the pallet stocker in order to provide convenient system expansion. The PALLETECH HIGH RISE SYSTEM features a 2/3-level pallet stocker for increased storage capacity with a minimum floor space requirement. Either the PALLETECH MANUFACTURING CELL or PALLETECH HIGH RISE SYSTEM can be selected according to current production requirements and budget. Either system can be easily expanded after the initial installation in response to increased production requirements.

Loading Station

When a pallet is at the loading station, the pallet can be indexed to 4 positions at every 90 degrees for convenient workpiece loading and unloading.

Additionally, the loading station is equipped with a safety door as standard equipment to maintain a safe working environment for the operator. The PALLETECH SYSTEM can be equipped with up to a maximum of 8 loading stations.

Pallet Loader

Pallets are automatically transferred from the pallet stocker to the loading station and then to a machining center by the pallet loader. The system controller commands the pallet loader according to the registered production schedule. The pallet loader features high speed acceleration and positioning to eliminate non-productive pallet waiting time. Additionally, the loader utilizes 2 different pallet transferring speeds - one when a workpiece is on a pallet and the other when no workpiece is on a pallet.

Applicable models:

| HCN | |

|---|---|

| INTEGREX i-V | 500V/5, 800V/8, 800V/8S |

| HCR | 5000, 5000S |

Palletech Videos

The HCN-8800 + PALLETECH has been installed in a customers factory in the Czech Republic. See it in action!

Watch Video